Introduction

Earlier this month Tweakers.net had the opportunity to take a look inside the Dane-Elec memory factory in Galway Ireland. Needless to say, we couldn't let this opportunity slip away, and so Femme (founder of Tweakers.net) and Wouter went to Galway to see the place where all of Dane-Elec's memory for the European market is produced.

Earlier this month Tweakers.net had the opportunity to take a look inside the Dane-Elec memory factory in Galway Ireland. Needless to say, we couldn't let this opportunity slip away, and so Femme (founder of Tweakers.net) and Wouter went to Galway to see the place where all of Dane-Elec's memory for the European market is produced.

Before we get into the actual producing process we'll give you a little info about the organization behind Dane-Elec. The company was founded in the year 1985 by the French David Haccoun en Nessim Bodokh, who got to know each other 2 years before, because they worked at the same department. These two guys decided to start for themselves, an started their own company involving alarm systems and passing on all kinds of electronic components. After two years of 'getting to know the market' they decided to specialize in distributing memory for computers.

Aireal shot of Dane-Elec Galway

Because the process of making memory requires large investments and know-how, they sticked to selling third party components and products. Soon Dane-Elec became a large European distributor for the Japanese brand OKI, but also Samsung and siemens were sold. Their ambition was to make their own memory sticks. And so, in 1996 they opened a factory in Galway. Two years after that they opened a small facility in Irvine, California. This factory however is a lot smaller that the building in Galway

Dane-Elec is still managed by David (CEO) and Nessim (COO), from their headquarters in France. Besides managing and selling from France, they also have their Research and Development there. The company has contacts will all the large players in the memory market and went to the stock market in 1997. Because of their success they opened offices in The Netherlands, Belgium, Germany and England. The Irish factory delivers to all the European sellers. The American division of Dane-Elec is independent; the complete production for the American continent is done in California.

Dane-Elec is still managed by David (CEO) and Nessim (COO), from their headquarters in France. Besides managing and selling from France, they also have their Research and Development there. The company has contacts will all the large players in the memory market and went to the stock market in 1997. Because of their success they opened offices in The Netherlands, Belgium, Germany and England. The Irish factory delivers to all the European sellers. The American division of Dane-Elec is independent; the complete production for the American continent is done in California.

The Factory

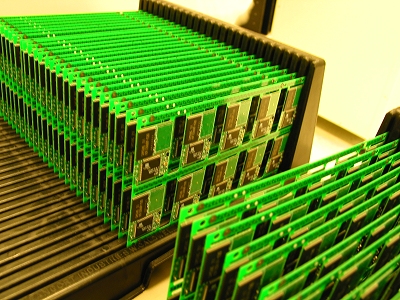

The Irish factory is located near Galway, a city with about 70.000 inhabitants. They have about 140 employees, who work in three shifts to keep the five production lines - divided across a large hall with a size of approximately 2300 square meters - running 24 hours a day 365 days a year. If needed, they can make about 20.000 memory modules a day.

The Irish factory is located near Galway, a city with about 70.000 inhabitants. They have about 140 employees, who work in three shifts to keep the five production lines - divided across a large hall with a size of approximately 2300 square meters - running 24 hours a day 365 days a year. If needed, they can make about 20.000 memory modules a day.

Earlier, this kind of capacity was needed very much to meet demand, and they even thought about expansion for a while. Nowadays the market is a lot less demanding, and because of that, the factory only runs at a 100% around Christmas. A factory like this does not use mass production. You can order dozens of different types of modules. The software the machinery uses can be changed within a few minutes to use different PCB's or components. They made hundreds of these programs for all kinds of different memory chips and components - ranging from EDO-SIMM to RDRAM.

The latter one is not produced in Galway. The testing equipment for RDRAM is very expensive, and because there is a relatively low demand for RDRAM, Dane-Elec decided to buy this kind of memory somewhere else and to just distribute it. Products like cardreaders and Smartmedia cards follow the same principle as RDRAM.

Besides the large range of products and the security of the warehouse there is another important argument not to work with large stocks. Money. The prices on the memory chips market are, as everybody knows, strongly under the influence of fluctuating prices. To keep the damage to a minimum they buy their products 'on-spot'. Various companies - i.e. Toshiba, Samsung and Infineon - store their chips in a large vault within the Dane-Elec factory. Although the memory is ready to use, it remains property of the companies mentioned above. As soon as an order arrives at Dane-Elec for modules and the chips are removed from the vault for production, the actual transfer takes place for the, at that moment, going price. The advantage of this is, that the modules can profit directly from price changes.

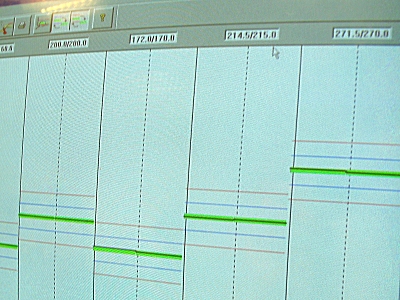

An impression of the production hall

Productionline number 2

Dane-Elec is not (yet) that big to make their own chips, and they don’t have a real 'cleanroom' like Intel or AMD use to place their wafferscanners. But they do try to keep the production room as clean and dust free as possible. This is to prevent that dust particles ruin a memory module by creating a faulty contact. Static electricity is another problem for the plant. Every desk has anti-static on it and everybody who wishes to enter the plant has to use a special jacket and an ankle-bracelet to ground themselves.

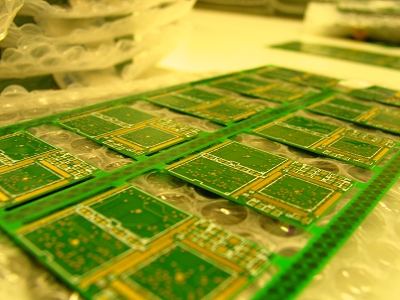

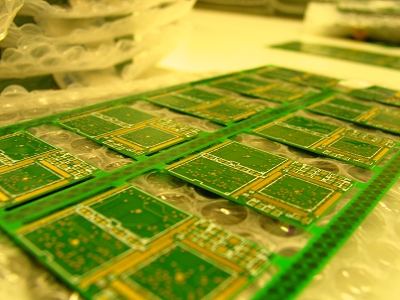

Preparing the PCB's

How the orders are processed here in Galway will be explained in the next few pages using a lot of visual material. Unfortunately it was impossible to take a picture of every little detail in the plant. Part of the equipment was labeled top-secret. Sadly to say, but in this industry people introduce themselves as potential buyer, seller or journalist to find out what kind of testing equipment Dane-Elec uses or to find out how Dane-Elec manages to produce their ComplactFlash memory so fast. That is why all the pictures we wanted to bring home from the plant had to be screened by the head of production.

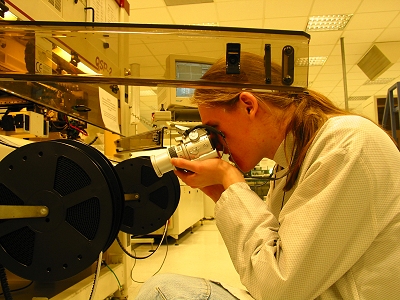

Femme taking a peek

Back to ordering. An order exists out of 5 to 2000 modules. These can be different types of modules. Larger orders are split up into work orders of 2000 modules per order. This first step is to collect the necessary components from the warehouse. Think of PCB's, resistors, chips etc.

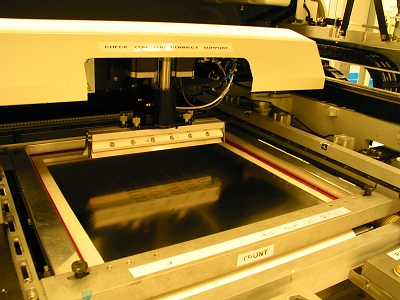

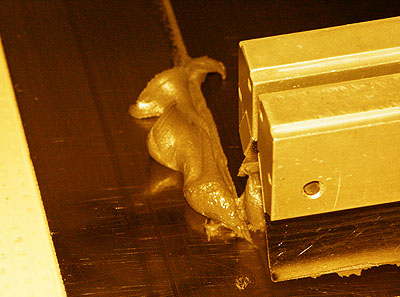

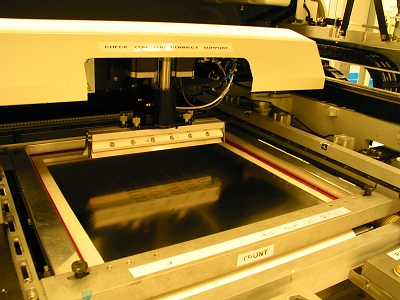

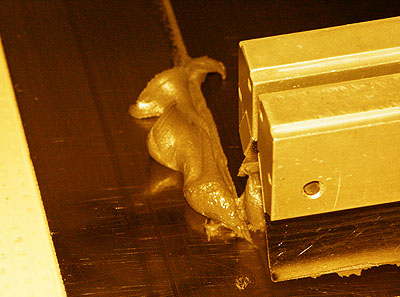

The PCB's are then placed into a feeder, which sends them to a screen printer. This printer uses a very precise pump mechanism, controlled by a special camera, to stamp the correct pattern of soldering paste on the PCB. This has to be done before any components are placed on the PCB's, because they stopped using PCB's with holes in the bottom which can be soldered eons ago. The paste in raw form is a very toxic gray mass, but also very expensive because it (amongst others substances) has silver in it. This is not only good for looks, but also good for conduction.

The screen printer - in the reflection you can see where the PCB's are supposed to be

Solder paste

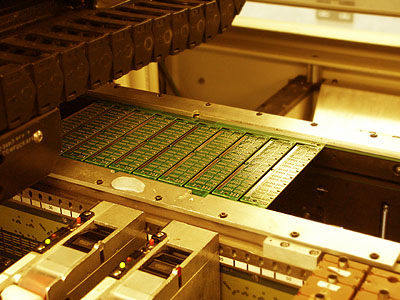

This is where the wannabe-modules come out

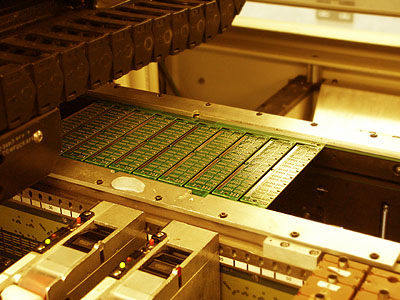

The PCB's go to a Philips Sapphire Machine through a conveyor belt. This machine can put a small component on 6 PCB's in less that a second. The robot arm is fed by special rolls and can hold 24 different types of small components. The computer that controls the robot arm on the sapphire machine relies on information from a high-resolution 10x zoom camera, to put the components in the correct place.

Sapphire in all it's 1337-ness

The inside of the machine

The moving robot arm with 24 heads

One of the highly sensitive camera's

Supplying parts to the machine

The mechanism that takes the resistors from the roll to the machine

No shortage here…

Mounting the memory chips

The Sapphire machine mentioned on the previous page can only put small parts onto the PCB. The Topaz machine is used to put the bigger parts onto the PCB. This machine is also a Philips-product like the Sapphire. The basic construction of both machines is very similar. The difference between them is that the Topaz can handle parts accurate to 32 millimeter (memory chips) due to a intelligent system which is called: on-the-fly vision alignment. With the help of small movable cameras this machine can handle smaller parts but the Sapphire is preferred to handle this task. The latter one does about 24.500 units per hour while the Topaz does 'only' a mere 14.000 in the same time.

Every piece of equipment is kept very clean

The memory chips a packed on large rolls

...and are individually packaged as well

For every type of module a different program has to be loaded

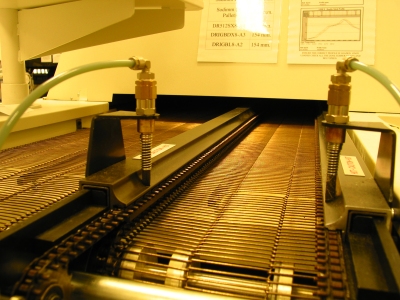

When every part is in the right place the moment of baking the chip starts. The chips are put into the oven. Dane-Elec prefers to call it: computerized thermal processing system. The oven has to do the following; vaporize a part of the paste, melt another part of it and finally harden a part of the paste again on the PCB. In the end all the placed parts have to be stuck on their mounted spot. Very high temperatures are needed in this process. Overclockers can tell you that only a few processors will survive temperatures higher than 100 degrees Celsius, but the memory chips have to withstand temperatures almost three times higher in the oven.

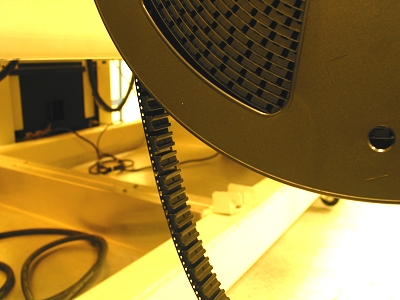

The oven

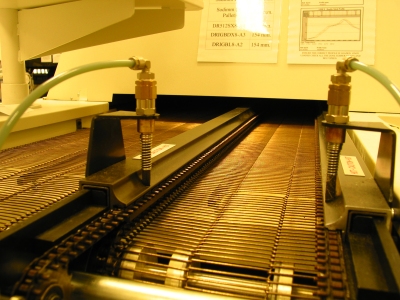

To use the entire width of the oven, the computer can move the conveyor belt

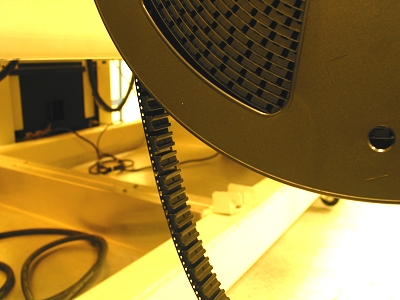

Fingerguards, but probably not your average 80 x 80 fan

For people who do not understand that things in an oven get hot

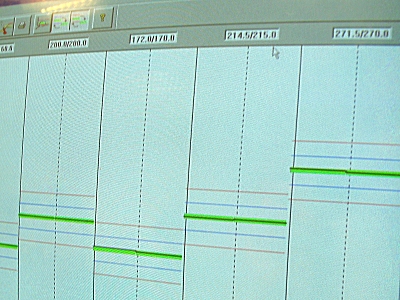

The manufacturer of the memory chips develops a model in cooperation with the supplier of the welding paste. This model is designed in such a way that the chips can be welded in the oven without breaking down. The chips can withstand temperatures of over 270 degrees Celsius two times in a row. The reason for this is that double sided memory has to pass the production line twice.

Temperature configuration of the oven

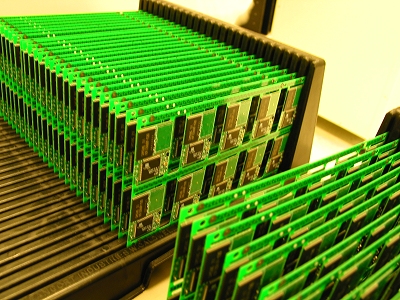

When the modules leave the oven they are put into a feeder on the other end of the production line. Lamps indicate if there is still place available otherwise it indicates it's time to empty the feeder. The distance the PCB totally covers is 20 meters from on end to the other end of the feeder. The finished modules are immediately sterilizedand labeled.

Endstation

CompactFlash

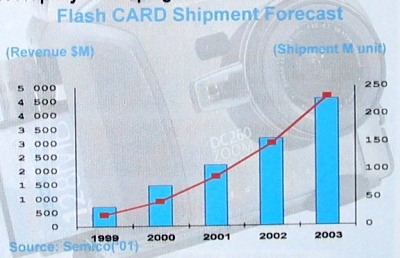

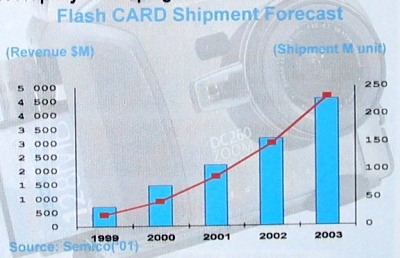

Although the larger portion of the plant is designed to make SDRAM and DDR memory, the demand for Compactflash is increasing. Especially the demand in Holland is getting bigger and bigger. Us Dutchies are a pain in the ass' according to the people who work there  . We want special retail boxes, while stores in other countries don�t see the need for it or the do it themselves.

. We want special retail boxes, while stores in other countries don�t see the need for it or the do it themselves.

Bunch of 256 MB CompactFlash cards in neat little boxes for the Dutch Market

Expected growth in the world market for flashcards

The basics of making CompactFlash memory are not so different from the method to make SDRAM or DDR memory. The PCB is suited for 5 memory chips and one controller. The reason the controller is on the PCB and not the machine that uses the CompactFlash memory, is that support for faster and bigger is easier to realize.

CompactFlash PCB's

Chips for the CompactFlash PCB

CompactFlash machine

Enough storage for a few vacation shots

Once the PCB is ready, it has to be placed in the well known housing. This housing is delivered as 2 separate half�s and are welded together with the help of ultrasonic vibrations. Other manufacturers use a system where the housing folds together like a little box. Once the compactFlash has its housing, they are ready to be tested.

Quality and testing

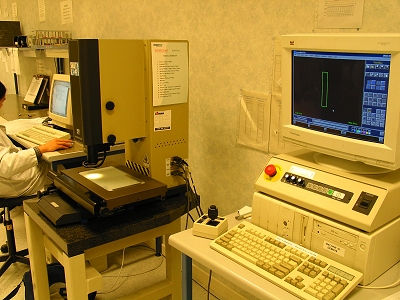

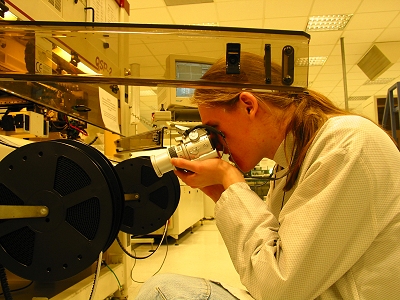

Because Dane-Elec markets their products as a so called A-brand, they have to see to it that the products they manufacture are of an excellent quality. Making good memory modules starts of course with the components. Their suppliers are hand picked, instead of just looking for the lowest price. This goes not only for the memory chips itself but also for all other parts and of course for the CompactFlash cards. Besides choosing the right supplier, they also check every new delivery by placing a percentage of the delivery under a microscope to be sure the quality is at the desired level.

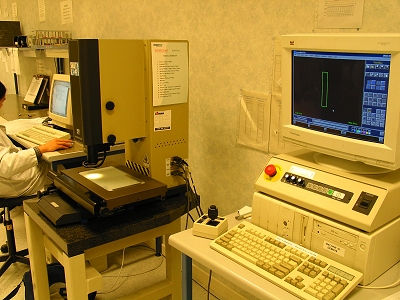

Near the entrance of the hall, a microscope is placed

During the process of making memory, there are also various optical tests. Although it is unlikely that the very expensive machines make errors, there is always a small possibility of malfunction or human error. Using a special scheme, the person working on the machine checks to see if everything comes out all right.

The company owns highly advanced and automatic testing equipment, which is used to test a certain percentage of every order. The height of the percentage depends on how many experience they have with a certain product. If malfunctions are discovered in one of the shipments, they increase this percentage. With the help of a large database they can track where, when and by whom the product was manufactured. By combining this data with their own test results and the information gathered by their RMA department, they are able to pinpoint structural problems.

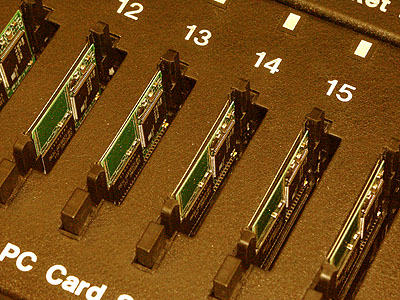

CompactFlash tester close-up

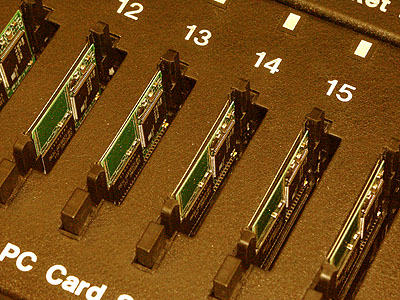

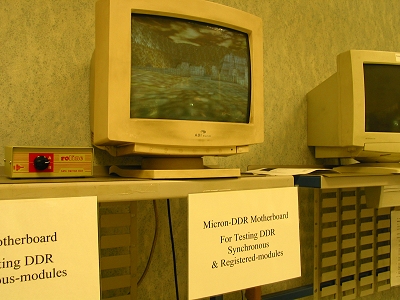

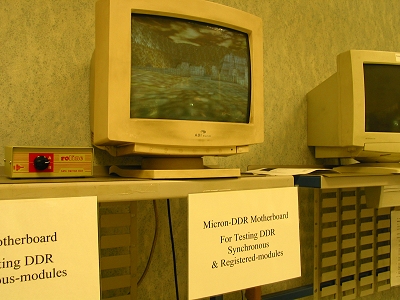

To test modules for which they do not have automatic equipment, or to test compatibility, they use a whole series of different computers. Old 486 machines, laptops and dual CPU servers are sometimes running Quake III for days and days. All this to be sure that things don't crash due to a faulty memory module.

Micron moederbord? Mamba chipset?

The future and conclusion

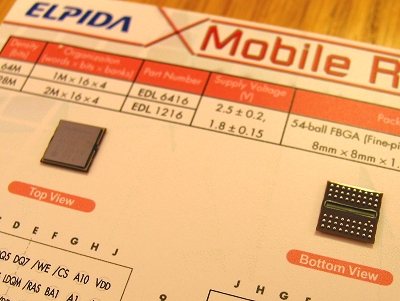

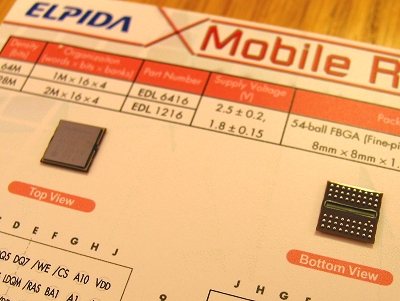

The large step Dane-Elec is waiting for is DDR-II. There were samples present at the factory, but they were not yet able to make the modules because the Topaz machines - the ones that place the chips on the PCB�s - still have to be equipped with x-ray camera�s. DDR-II uses a µBGA packaging instead of normal FCPGA. This makes the chips smaller, but besides that, they also have attachment points in the middle of the chips, which make it impossible to see all of them with a normal camera. Later this year the machines will be adjusted accordingly and they will start running test productions. Probably DDR400 or DDR533. It is yet uncertain if they are going to produce the DDR-I version of DDR400, but if the market requires it, the software of the machines can easily be adjusted to manufacture them.

A DDR-II memory chip from Elpida

As we al know the memory chips market has gone through some rough times the past year, and despite the fact that there have been signs of improvement, the level from before the crisis is still very far away. Dane-Elec is - like a dozen other companies - still losing money. Still, that�s no reason to give up hope. Memory is a product that the world can�t live without and there will always be a demand for it. New ways of distributing (like supermarkets) and a new generation of products like organizers and digital cameras which hunger for storage, combined with the fact that there is a new 'upgrade phase' coming for a lot of companies, make Dane-Elec believe they can make money again this year instead of losing.

Everybody here already knew Dane-Elec as a sponsor For Tweakers.net or as a brand name on one of the many products sold at shop.tweakers.net, but by writing this review we hope to have given everybody a better image of the work Dane-Elec does, as a company, and also memory manufactures in general. Other companies use the same basic procedures, components and equipment. Unfortunately we were not allowed to reveal the small details that differs Dane-Elec from the rest, but we can be sure that every company has their own little secrets.

We would like to thank Dave Lalor for allowing us to tour his factory, our tour guide Ethan (is that spelled correctly?  ) for all the information and paying our Chinese food, his uncle for driving us around early in the morning in his spare time, Rob Bruin for arranging the trip, and Jan Bolder for kicking Rob every day to get it done

) for all the information and paying our Chinese food, his uncle for driving us around early in the morning in his spare time, Rob Bruin for arranging the trip, and Jan Bolder for kicking Rob every day to get it done  .

.

Furthermore BrZ, Gump, Reefer, Sarcast and all the others for the translation from Dutch to English.

Typical Irish (?) Small street with a lot of bars |  This little souvenir had to be given back |

Found an internet connection at Shannon Airport |  It flew |

Earlier this month Tweakers.net had the opportunity to take a look inside the Dane-Elec memory factory in Galway Ireland. Needless to say, we couldn't let this opportunity slip away, and so Femme (founder of Tweakers.net) and Wouter went to Galway to see the place where all of Dane-Elec's memory for the European market is produced.

Earlier this month Tweakers.net had the opportunity to take a look inside the Dane-Elec memory factory in Galway Ireland. Needless to say, we couldn't let this opportunity slip away, and so Femme (founder of Tweakers.net) and Wouter went to Galway to see the place where all of Dane-Elec's memory for the European market is produced.

Dane-Elec is still managed by David (CEO) and Nessim (COO), from their headquarters in France. Besides managing and selling from France, they also have their Research and Development there. The company has contacts will all the large players in the memory market and went to the stock market in 1997. Because of their success they opened offices in The Netherlands, Belgium, Germany and England. The Irish factory delivers to all the European sellers. The American division of Dane-Elec is independent; the complete production for the American continent is done in California.

Dane-Elec is still managed by David (CEO) and Nessim (COO), from their headquarters in France. Besides managing and selling from France, they also have their Research and Development there. The company has contacts will all the large players in the memory market and went to the stock market in 1997. Because of their success they opened offices in The Netherlands, Belgium, Germany and England. The Irish factory delivers to all the European sellers. The American division of Dane-Elec is independent; the complete production for the American continent is done in California.

The Irish factory is located near Galway, a city with about 70.000 inhabitants. They have about 140 employees, who work in three shifts to keep the five production lines - divided across a large hall with a size of approximately 2300 square meters - running 24 hours a day 365 days a year. If needed, they can make about 20.000 memory modules a day.

The Irish factory is located near Galway, a city with about 70.000 inhabitants. They have about 140 employees, who work in three shifts to keep the five production lines - divided across a large hall with a size of approximately 2300 square meters - running 24 hours a day 365 days a year. If needed, they can make about 20.000 memory modules a day.